On a recent trip to see what technology Todd Wynne and the rest of the team at Rogers-O’Brien Construction (RO) have been tinkering with, I had a chance to experience firsthand which new hardware innovations will one day be applied in the AEC space.

One of the “future” technologies being used today is showing some promise and already has a definable ROI. Quadcopters have taken the AEC space by storm. For around $1,500, this visualization aid has many applications for gathering and communicating jobsite information.

Rogers-O’Brien is currently testing the use of quadcopters for use in weekly site reporting. With the Federal Aviation Administration (FAA) still trying to figure out how to best regulate small “hobby” and “prosumer” users, safety is the number one priority.

Blake Potts, Wynne’s colleague, is overseeing the implementation and use of these aerial devices. He has even begun to assemble a comprehensive flight manual, which gets loaded onto iPads with form field PDFs for easy data entry. These PDFs include pre-flight checklists to document wind speed and weather prior to takeoff. A flight plan is also required, which takes into account cranes and other potential obstacles.

Progress is being made with the FAA’s acceptance of drones for commercial use on construction sites. Just this week, the FAA granted Trimble Navigation Limited, VDOS Global, Clayco, and Woolpert, along with seven film and video production companies, regulatory exemptions to fly drones in national airspace.

According to a recent article in Forbes, the exemptions were granted in accordance to Section 333 of the FAA Modernization and Reform Act. The application process is lengthy and requires that firms demonstrate that their use of the drones will not pose a threat to national airspace or national security. The article also states that to date the agency has received 167 requests for exemptions from commercial entities.

This is a big win for firms like Rogers-O’Brien, who have already begun to see major benefits returning real value for the innovation team. The $1,500 investment pays for itself within a few flights, depending on the mission.

One particular mission saved the project over $15,000 in warranty work. A 13-story building was experiencing some precast leaking. Normally, in order to inspect the area, they would have had to erect scaffolding or suspend an inspector over the building edge to access the area and take photos for the risk manager.

Based on the size of the inspection area, they would have to erect, tear down and re-erect scaffolding. This job that would have taken over four days and cost them $1,500 for every 15 feet moved was done in a one-hour quadcopter flight.

The video and images taken were shared with the risk manager, who determined the best way to solve the issue, saving them time and thousands of dollars in warranty work.

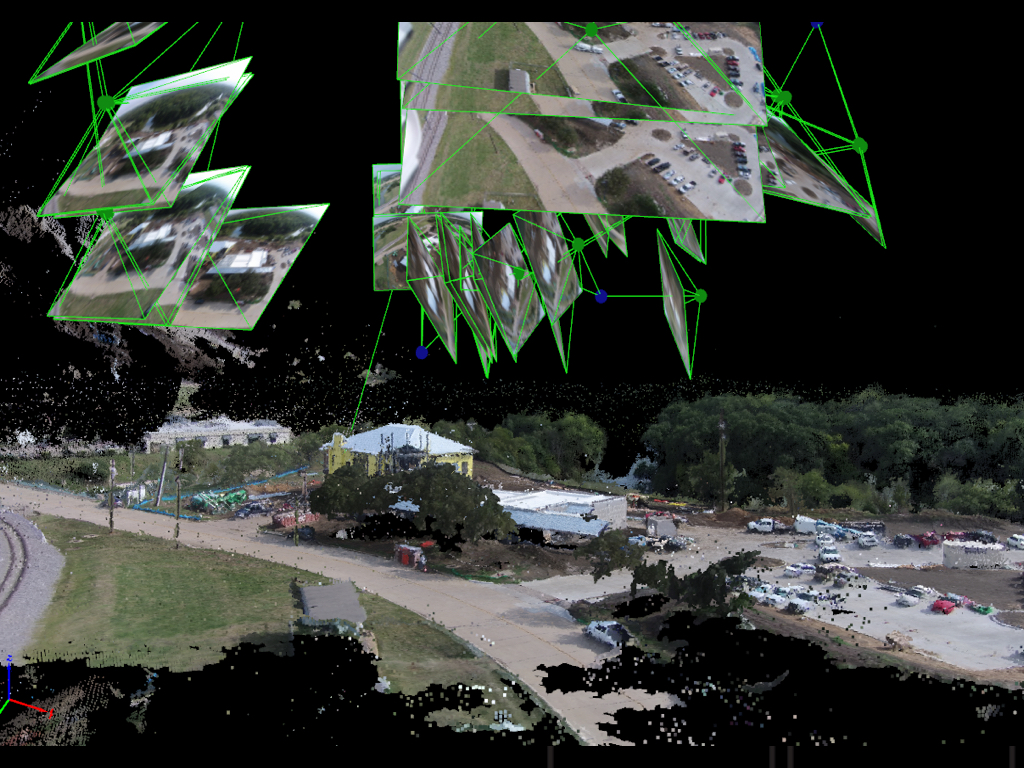

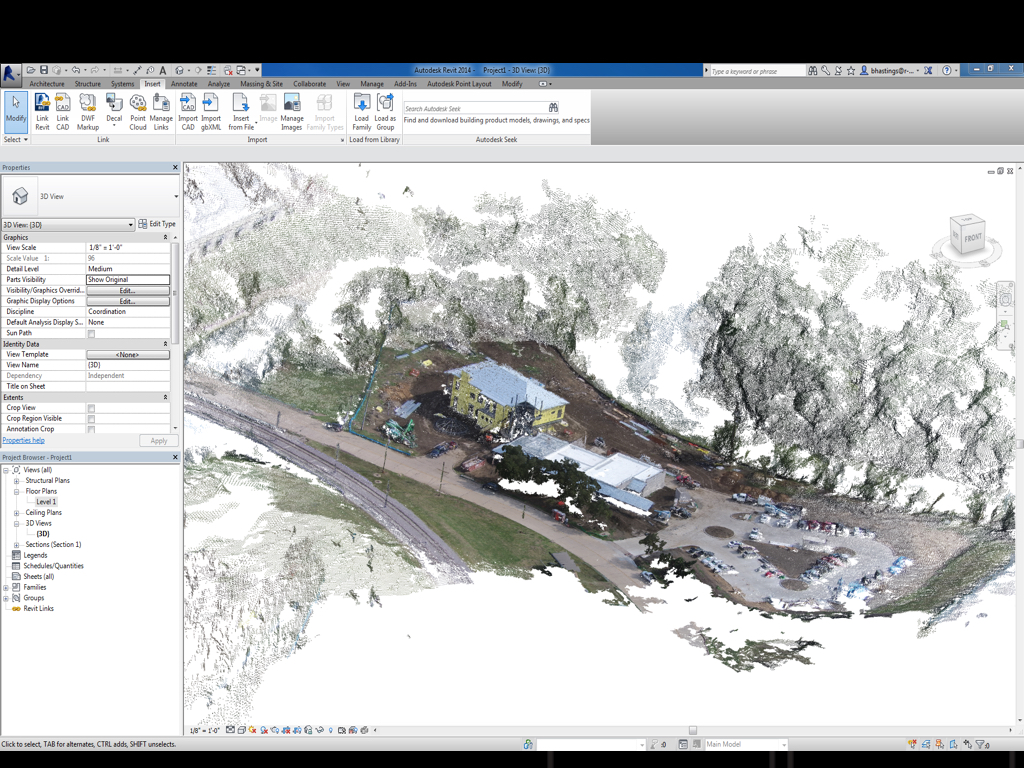

The drones are primarily being used for aerial inspection and progress photos today, but Potts sees potential for live feeds to the office, with photogrammetry or laser scanning from photographs collected during flight. Putting that theory to the test, the RO team has begun using their quadcopter for Reality Capture. Using visualization software called Pix4D, they’re able to turn photos into models that document existing conditions, as-builts, visualization, and 3D printing. Wynne says it’s like laser scanning with photos.

In my last blog, I shared how the RO team was leveraging FLIR, a thermal technology device for the iPhone, to troubleshoot HVAC and plumbing issues in the field. Taking that idea a step further, the team designed, built and manufactured their own custom mount using a 3D printer. They’ve combined UAV technology (DJI Phantom Quadcopter), 3D printing, and the FLIR thermal camera to conduct roof inspections. The alpha version of this system was successfully flown in October of this year with plans to refine the system further in 2015.

Since starting this project in 2014, the company to date has utilized 6 quadcopters, taken over 14,000 photos and captured 331 movies. The team believes this technology will allow owners in the future to keep eyes on their job site from anywhere in the world.

More from Author

Sasha Reed | Dec 15, 2017

Future vs. current state of construction innovation: How will we make the leap?

Looking beyond today’s constraints to the possibility of what “could be” is a key characteristic of those defining and delivering innovation to design and building firms across the globe.

Sasha Reed | Sep 19, 2017

BIM vs VDC…how the US and the UK differ in approaching digital project delivery

In this four-part series, Bluebeam VP Sasha Reed sat down with industry experts to examine the need for defining and understanding digital workflows and data management throughout the design and construction project lifecycle.

Sasha Reed | Jul 19, 2017

Introducing StrXur by Bluebeam

Our goal is to present unique perspectives you may not be able to find anywhere else.

Sasha Reed | Jul 13, 2017

Defining the future by mastering the art of change

From my perspective, what separates organizations thriving in the digital revolution from those who are not boils down to one thing: leadership.

Sasha Reed | Mar 15, 2017

Incentivizing change: Show me the money

Who is succeeding, and on what terms? And what will it take for everyone to experience the benefits of that success?

Sasha Reed | Oct 4, 2016

The talent shortage: Will the training the AEC industry desperately needs arrive in time?

As the construction industry bounces back from the Great Recession, an entirely new class of tech-savvy construction professionals has been created, and the supply of these highly skilled, tech-proficient pros has been quickly exhausted.

Sasha Reed | Jul 11, 2016

Construction Disruption at AECX: Technology, hackathons and the promise of change in LA

The lead up to AECX featured a discussion providing insight into the current state of the AEC technological revolution by exploring opportunities, challenges and choices AEC pros face.

Sasha Reed | Jun 23, 2016

Implementing Change: The Five Biggest Mistakes to Avoid

Two truths from the jobsite: 1) The best part about uncovering a problem is discovering its solution, and 2) The worst part about discovering the solution is implementing it.

Sasha Reed | Jun 9, 2016

With all these sharks in the water… (No Predictions Here...Part 2)

Rather than fighting to control the proliferation of apps, perhaps we should be training our eyes to look for signs of long-term viability among all the fins in the water