When it comes to fire rated glass, there is probably nothing more confusing than the 60-minute application – what product to use, how much of it, and what happens when sprinklers are present. While the temptation to use a one-size-fits-all fire rated product advertised as ‘unlimited’ with ratings ‘from 20 minutes to 3 hours’ seems appealing, this statement is very misleading and can potentially cause a costly project rejection.

Test labs list products in ratings and sizes that are not allowed in the IBC. Remember, a listing only tells you what the product has been tested to – not if it meets your application’s code requirement. As an example, ceramics are listed with an “OH” for 60 minute sidelites, transoms and openings, which means it was tested to NFPA 257, the fire window standard indicating that it blocks smoke and flames, but does not limit radiant heat. However, the IBC requires glazing in sidelites, transoms and openings over 45 minutes to be marked with a “W”, indicating that it meets ASTM E-119, wall standard which limits the passage of radiant heat. Thus, ceramics having an “OH-60” listing for 60 minute sidelites, transoms and openings misleads architects and specifiers to believe that it can be used in these locations. Quite the opposite is true because according to the Chapter 7 tables in the 2012 and 2015 IBC, these applications require a “W-60” listing to indicate that the glazing product meets the fire resistive ASTM E-119 criteria – something that ceramics clearly do not.

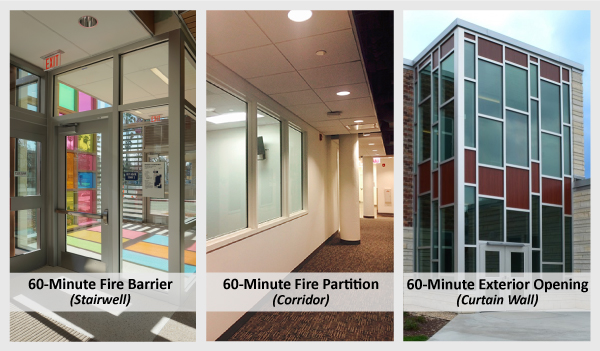

How can this confusion be avoided? It’s important to look beyond the product’s duration rating and focus on the application requirements instead. There are several areas in a building that are rated for 60-minutes but have very different code requirements depending on their application, which controls product selection. Here are some of the most common:

60-minute Fire Barriers

The IBC defines fire barriers as “a fire-resistance rated wall assembly of materials designed to restrict the spread of fire in which continuity is maintained.” In a building, 60-minute fire barriers are usually used as shaft enclosures, exit access stairways, exit access ramps, interior exit stairways, interior exit ramps and exit passageway walls.

Because a fire barrier functions to limit the spread of fire, materials such as masonry and gypsum walls are traditionally used because these materials meet ASTM E-119, the fire resistive wall criteria that ensures that radiant heat passing through building materials and into the non-fire side is limited. The radiant heat generated in a fire is so intense that it is enough to ignite combustible materials without having contact with the flame, which contributes to fire spread. Even worse, the intense radiant heat builds up within minutes and without an ASTM E-119 rated material used, building occupants can suffer severe burns, which makes safe egress impossible. This is a real problem because 60-minute shaft enclosures, exit access stairways, exit access ramps, interior exit stairways, interior exit ramps and exit passageway walls are the required egress routes in a building, or a safe haven where occupants can await rescue.

This is why any glazing used in these applications must limit radiant heat which ceramic glazing does not. Here are the glazing options for the different applications allowed in Table 716.5 and 716.6 of the 2012 and 2015 IBC:

Door Vision Panels in 60-minute Fire Barriers: fire protective glazing such as ceramics and wired glass are limited to 100 sq. inches because they are unable to limit radiant heat. The code does allow designers to exceed 100 sq. inches in the door vision panel as long as fire resistive glazing is used that meets ASTM E-119, not a fire protective product such as ceramic or wired glazing.

Sidelites and Transoms in 60-minute Fire Barriers: If a designer would like to have sidelites and transoms as part of the door assembly, ASTM E-119 rated fire resistive glazing rated equal to the wall must be used. Fire protective glazing is not permitted because it does not meet ASTM E-119. The framing used must also meet ASTM E-119 for the same reason to make a code-compliant assembly. Fire protective glazing like glass ceramics or wired glass in combinations with standard hollow metal frames, though tested to 60-minutes, cannot be used in this application as they don’t contain radiant heat as required by ASTM E-119.

Windows or Openings (other than sidelites and transoms) in 60-minute Fire Barriers: fire protective glazing is not allowed in windows or openings in these fire barrier applications because it doesn’t meet ASTM E-119. If the designer would like to use glazing in these areas, the only choice is glazing that meets ASTM E-119. The framing used must also meet the same ASTM E-119 requirements. Fire protective glazing like ceramics and standard hollow metal frames, though given a rating a rating of 60-minutes, do not carry a “W” or meet the ASTM E-119 requirement for this application.

The code has strict requirements for glazing used in 60-minute fire barriers because of the devastating effects of radiant heat on the spread of fire and potential harm to the building occupants. In addition, all of these requirements apply in fire barrier areas whether or not sprinklers are present – there are no trade-offs allowed. Research has shown that sprinklers can and have failed before, so the need for built-in protection that blocks smoke, flames and severely limits the passage of dangerous radiant heat through the glazing is very important. Life safety is especially critical in these areas of the building (shaft enclosures, exit access stairways, exit access ramps, interior exit stairways, interior exit ramps and exit passageway walls).

Next: IBC requirements for 60-minute fire partitions, corridors and smoke barriers.

Click here for the full article.

More from Author

Bill O'Keeffe | Oct 19, 2020

Going virtual

Manufacturers use virtual platforms to help architects meet CEU requirements.

Bill O'Keeffe | Jul 16, 2020

Obsolete?

"Revolutional, affordable, USA made Fire Rated Glazing for all fire protective areas makes ceramic glazing obsolete". Check out SuperClear 45-HS and SuperClear 45-HS-LI to understand why!

Bill O'Keeffe | Feb 10, 2020

USA-made fire rated glazing goes big in 2020

We are pleased to announce and share that the second phase of this $8 million expansion, upgrading our fire rated glass manufacturing facilities in Merced, California, is underway.

Bill O'Keeffe | Nov 20, 2019

Demand for advanced, USA-made fire rated glazing “RAISES THE ROOF”

With architects specifying full-vision, code-compliant, 60 and 90 minute, temperature rise doors for exit stairwells and other code required applications, we found this as an opportunity to expand our product offerings.