Advances in the research and treatment of personalized medicine are making huge waves in the life sciences industry—especially in California. In fact, three of the top 10 ranked life sciences clusters are in California: No. 2, San Francisco; No. 3, San Diego; and No. 9, Los Angeles. Personalized medicine is one of the hottest trends in life science, so there is reason to take note of how the big shift will affect new and existing life science facilities.

Personalized medicine differs significantly from “traditional” research and development processes and is affecting the pharmaceutical manufacturing market in major ways. First, because the therapies produced for personalized medicine are targeted, manufacturing space is shifting from large-scale to small-scale and requires less validated piping and more single-use tubing and products. Second, manufacturing small amounts of these individualized therapies requires technology and equipment that are even more specialized—so having the deep expertise to design optimized, flexible laboratories is crucial.

There are two possible situations that start-ups and developers are encountering at this critical moment: they have existing manufacturing facilities that are not built to address current personalized medicine requirements, or they have available empty shell space for manufacturing that is ready to be designed for small-scale manufacturing. Below are a few major considerations these organizations should consider for small-scale lab manufacturing success.

Be Future-Focused

In this exciting world of personalized medicine, the spaces we design must be able to respond on a dime to evolving innovations and changing technologies. A laboratory designer who specializes in small-scale lab manufacturing should work with your team to anticipate space needs far into the future. We are seeing industry advancements such as Green Chemistry and 3D “bioprinting” technology that are completely changing current Good Manufacturing Processes (cGMP) and decreasing some typical standard process needs. The increased use of AI to complete redundant tasks is also affecting the way we design QA/QC laboratories and other support spaces. Having a broad understanding of how future innovations and technology can influence design saves time and money when planning a manufacturing space.

Understand Your End-User

Personalized medicine research and development requires the highest-quality individualized environments. Understanding the end-users who will ultimately occupy your space is critical. To design a truly innovative facility that will stand out to potential tenants or internal teams, consider both current design factors and possible building solutions that can be incorporated into the design now to adapt to future technology and manufacturing processes.

Also, consider what your end-users will manufacture within the facility. What public spaces will facilitate each user’s mission and culture? Often, the design focus is only on spaces that the FDA will visit and audit, but what about spaces intended to wow potential investors, patients and press? Support spaces often become important at this stage—not only for the scientists and researchers who occupy the space, but also for external audiences whom they need to impress.

Ensure Your Site is Large Enough

Even with this smaller-scale manufacturing, careful consideration and allocation of site space are essential to ensure necessary utilities perform optimally. Make sure there are adequate pads for outdoor generators. There are also many other utilities to consider, including cooling towers, transformers, gas, and delivery of materials. We recommend including a multi-story warehouse space with a full-height mechanical mezzanine. Additionally, loading requirements and truck turnarounds will ensure that your site is flexible enough for different forms of manufacturing.

Consider Your Contamination Strategy

Often, there are too few streams dedicated to materials handling in and out of facilities. Contamination is a major risk for pharmaceutical manufacturing, and small-scale manufacturing only magnifies this risk. Ensure that the building has enough dock doors and that dedicated paths exist for moving new materials into, and waste out of, the facility. We know that waste streams must be separated with both dedicated doors and physical barriers. Establishing non-crossing waste, finished product and raw materials streams are essential to FDA validation.

Make Security a Top Priority

With personalized medicine comes cutting-edge innovations, technologies, and even processes that are proprietary; these systems and spaces require space design that ensures confidentiality. Manufacturing spaces must have a high level of security in place that strategically considers design elements, such as where natural daylight and views into the facility are appropriate. This level of security not only needs to be integrated internally, but also should be a part of the overall design of the facility. The facility should look exciting, open, and welcoming while also maintaining security levels to safeguard proprietary processes.

Realize the True Ratios for Support Space

It may be surprising how much support space is recommended for small-scale lab manufacturing. For a 5,000-sf ISO-8 and tighter classified space, the recommended support space size should be at least three times the ISO space. These support spaces are critical to the facility’s success. Be sure to consider airlocks, storage and direct support spaces as these areas are often overlooked in a facility plan. Additionally, mechanical and other building support spaces dedicated to clean rooms and clean room support require adequate space—whether on a full-height mezzanine or outside the building. These clean manufacturing support areas can occupy large amounts of space, so understanding the need for such space is essential to the facility’s overall design.

Related Stories

Sustainability | May 11, 2023

Let's build toward a circular economy

Eric Corey Freed, Director of Sustainability, CannonDesign, discusses the values of well-designed, regenerative buildings.

BIM and Information Technology | May 8, 2023

3 ways computational tools empower better decision-making

NBBJ explores three opportunities for the use of computational tools in urban planning projects.

Mass Timber | May 1, 2023

SOM designs mass timber climate solutions center on Governors Island, anchored by Stony Brook University

Governors Island in New York Harbor will be home to a new climate-solutions center called The New York Climate Exchange. Designed by Skidmore, Owings & Merrill (SOM), The Exchange will develop and deploy solutions to the global climate crisis while also acting as a regional hub for the green economy. New York’s Stony Brook University will serve as the center’s anchor institution.

University Buildings | Apr 24, 2023

Solving complicated research questions in interdisciplinary facilities

University and life science project owners should consider the value of more collaborative building methods, close collaboration with end users, and the benefits of partners who can leverage sector-specific knowledge to their advantage.

Laboratories | Mar 9, 2023

5 laboratory design choices that accelerate scientific discovery

Stephen Blair, director of CannonDesign's Science & Technology Practice, identifies five important design strategies to make the most out of our research laboratories.

University Buildings | Feb 9, 2023

3 ways building design can elevate bold thinking and entrepreneurial cultures

Mehrdad Yazdani of CannonDesign shares how the visionary design of a University of Utah building can be applied to other building types.

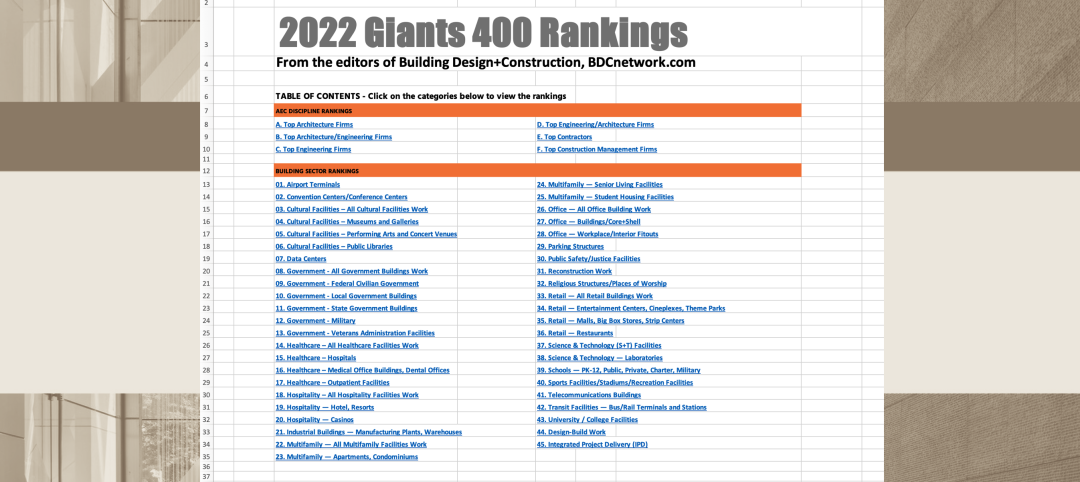

Giants 400 | Feb 9, 2023

New Giants 400 download: Get the complete at-a-glance 2022 Giants 400 rankings in Excel

See how your architecture, engineering, or construction firm stacks up against the nation's AEC Giants. For more than 45 years, the editors of Building Design+Construction have surveyed the largest AEC firms in the U.S./Canada to create the annual Giants 400 report. This year, a record 519 firms participated in the Giants 400 report. The final report includes 137 rankings across 25 building sectors and specialty categories.

University Buildings | Feb 7, 2023

Kansas City University's Center for Medical Education Innovation can adapt to changes in medical curriculum

The Center for Medical Education Innovation (CMEI) at Kansas City University was designed to adapt to changes in medical curriculum and pedagogy. The project program supported the mission of training leaders in osteopathic medicine with a state-of-the-art facility that leverages active-learning and simulation-based training.

Mass Timber | Jan 30, 2023

Net-positive, mass timber building will promote research on planetary well-being in Barcelona

ZGF Architects, along with Barcelona-based firms MIRAG and Double Twist, have designed a net-positive, mass timber center for research on planetary well-being. Located in Barcelona, the Mercat del Peix Research Center will bring together global experts in the experimental sciences, social sciences, and humanities to address challenges related to the future of the planet.

Adaptive Reuse | Dec 21, 2022

University of Pittsburgh reinvents century-old Model-T building as a life sciences research facility

After opening earlier this year, The Assembly recently achieved LEED Gold certification, aligning with the school’s and community’s larger sustainability efforts.