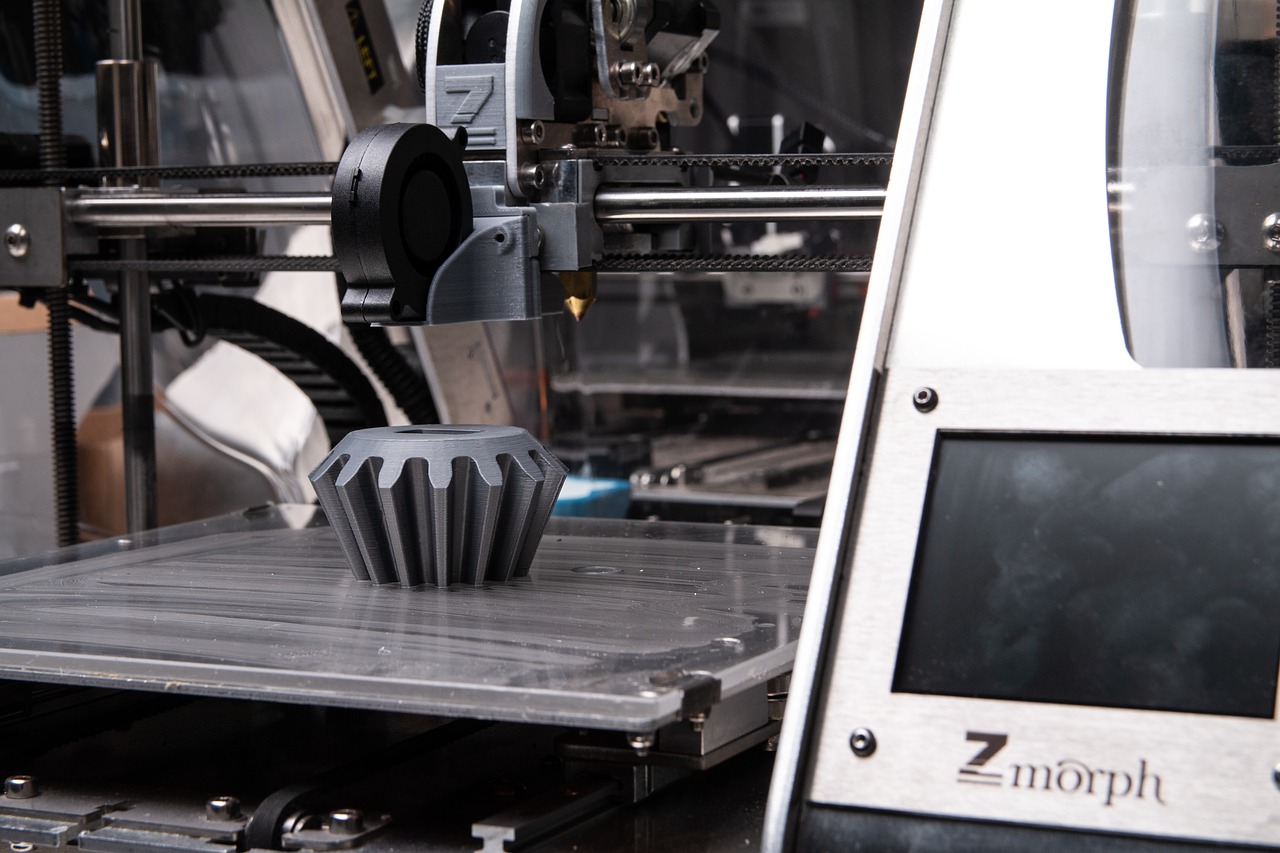

In recent years, the design firm Gresham Smith has seen the introduction of additive manufacturing into its industrial-sector work. “We have several clients that are using additive manufacturing to make production tools,” says David Verner, RA, Executive Vice President in the firm’s Industrial market.

Additive manufacturing (AM)—the process of fabricating parts and components from 3D model data—has emerged as a multi-billion-dollar business with considerable runway to grow.

“Almost all of our manufacturing clients are using additive manufacturing in their R&D operations,” says George Halkias, a Senior Principal with Stantec. A few of those clients have already layered aspects of AM onto their commercial processes.

Ware Malcomb has also seen increased demand for industrial facilities with additive manufacturing capabilities, especially in automotive and aviation fields that produce 3D-printed metal parts, says Michael Bennett, a Principal. He notes that among the specialized needs to support this technology are enhanced power, specific gases, and tank farms.

Additive manufacturing comes to the production line

Verner says that, in some cases, Gresham Smith’s team members are designing tools based on input from production-line workers. For example, it designed a replacement O-ring that once cost its client $20 per piece to produce. The client, says Verner, can now make that O-ring via onsite AM for less than 50 cents each. For replacement parts and tools described, the identified annual cost savings for this client is now almost $1 million.

Gresham Smith currently has under construction an AM R&D/contract manufacturing facility it designed. That site, says Verner, will build prototypes of parts and products from various materials, including titanium. The goal is to be able to build one or 100 items on demand cost effectively, he says.

Related content: Additive manufacturing heads to the jobsite

Clayco is a member of an executive committee that is exploring ways to bring AM to more industrial jobsites. The committee includes a real estate developer, designers, and AM companies. “We are analyzing the business model and preparing to implement AM onsite in a beta-test scale,” says Anthony J. Johnson, an Executive Vice President with Clayco.

Burns & McDonnell has developed an “additive playbook,” says Wade Anderson, Senior Project Manager, to help one of its clients identify key considerations that might influence design and construction, such as material storage and handling, cross contamination of materials, hazardous material requirements, air quality, power continuity, and special finishes.

Related Stories

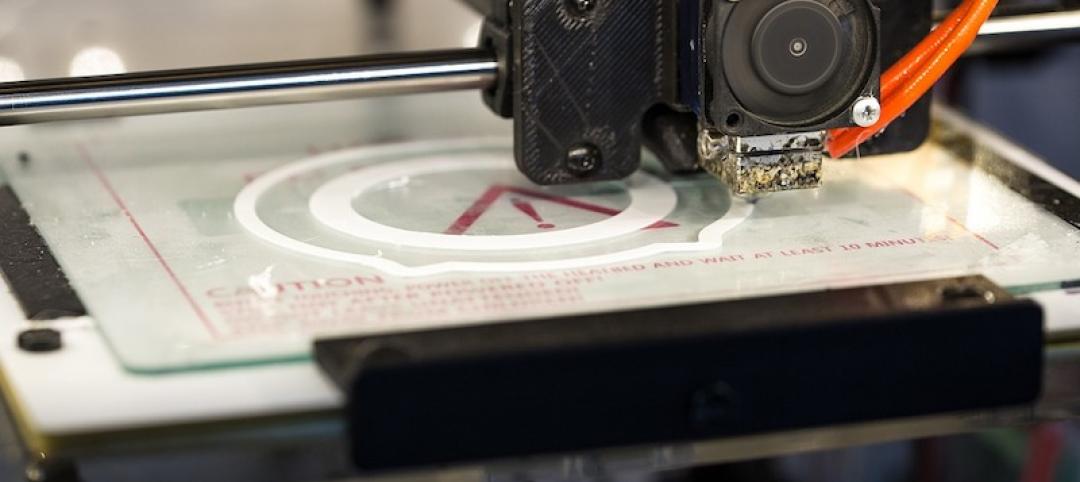

Coronavirus | Apr 4, 2020

COVID-19: Architecture firms churn out protective face shields using their 3D printers

Architecture firms from coast to coast have suddenly turned into manufacturing centers for the production of protective face shields and face masks for use by healthcare workers fighting the COVID-10 pandemic.

AEC Tech | Feb 13, 2020

Exclusive research: Download the final report for BD+C's Giants 300 Technology and Innovation Study

This survey of 130 of the nation's largest architecture, engineering, and construction firms tracks the state of AEC technology adoption and innovation initiatives at the AEC Giants.

3D Printing | Dec 10, 2019

6,888-sf Dubai Municipality building is the largest 3D printed building to date

Apis Cor 3D printed the building.

3D Printing | Jun 10, 2019

Thornton Tomasetti invests in 3D printing firm

XtreeE focuses on large-scale 3D-printing for the AEC industry.

3D Printing | Mar 14, 2019

Saudi Arabia just purchased the largest 3D construction printer in the world

COBOD developed the printer, dubbed the BOD2.

3D Printing | Dec 7, 2018

Additive manufacturing heads to the jobsite

Prototype mobile 3D printing shop aims to identify additive manufacturing applications for construction jobsites.

3D Printing | Aug 31, 2018

Marines built the world’s first continuous 3D-printed concrete barracks in 40 hours

Normally, it takes 10 Marines five days to build a traditional barracks out of wood.

3D Printing | Aug 29, 2018

Dubai plans to 3D print 25% of every new building by 2025

The Dubai Future Foundation recently announced the Dubai 3D Printing Strategy.

Accelerate Live! | Jun 24, 2018

Watch all 19 Accelerate Live! talks on demand

BD+C’s second annual Accelerate Live! AEC innovation conference (May 10, 2018, Chicago) featured talks on AI for construction scheduling, regenerative design, the micro-buildings movement, post-occupancy evaluation, predictive visual data analytics, digital fabrication, and more. Take in all 19 talks on demand.

| Jun 11, 2018

Accelerate Live! talk: How advanced digital fabrication techniques are driving design innovation

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), SOM’s Lucas Tryggestad and Kyle Vansice present the firm’s 3D-printed building project and explore how digital fabrication is pushing design innovation.