New glazing technology is rapidly unfolding. Currently available technologies are seeing performance gains, and cutting-edge products and systems continue to gain a foothold in the mainstream.

Examples of such technologies include:

1. State-of-the-art IGUs. In addition to construction improvements like warm-edge spacers, IGUs are beginning to benefit from alternatives to gas fills. Aerogel insulation, made of synthetic solids that consist almost entirely of air, exhibits extremely low thermal conductivity. Some aerogels can be integrated with polycarbonate sheets to form a translucent cladding material, while others, such as silica aerogels in granular form, can fill the spaces between the glass lites of insulating units, says Ajla Aksamija, PhD, LEED AP BD+C, CDT, Building Technology Researcher with design firm Perkins+Will.

Aksamija also mentions vacuum-insulated glazing (VIG) units. “These units use a vacuum between lites of glass to raise the assembly’s thermal resistance,” she says. With no gas or fill, conduction and convection are virtually eliminated, which also allows the space between the lites (and total glazing thickness) to be greatly reduced, enhancing design flexibility. Patterson notes that vacuum glazing holds the most promise for producing vision glass with a U-factor good enough to justify continuing to build highly glazed facades. He cautions, however, that “a viable solution for widespread application seems to remain beyond the horizon.”

2. Electrochromic glass. Often called smart glass, electrochromic glazing alters its transmittance characteristics when an electrical current is applied, through the use of a specialized lamination that essentially integrates shading into the glazing unit. For instance, one type of smart glass appears frosted until the current is applied, at which point it becomes nearly transparent.

This technology has been in the works for some time, but cost has been a drag on broad market acceptance. There have been problems with the sealants, which are part of the system that carries the electrical current, says Joshua Zinder, AIA, Founding Principal of Joshua Zinder Architecture + Design, who has worked with the products on several occasions.

“A broken seal means a lost electrical connection in the lamination field, which means a loss of the electrochromic functionality in one or more adjacent panels,” he warns, but manufacturers are working to address this problem. “Electrochromic glazing appears to be on the verge of widespread adoption,” says Mic Patterson, Vice President of Strategic Development for Enclos. “The industry has recently invested in the manufacturing infrastructure necessary to produce materials with the right combination of aesthetic and performance attributes at a tolerable price point. These dynamic glazing materials still leave the problem of thermal performance.” Nevertheless, more use of smart glass is likely due to its flexible VLT, which can be integral to daylighting strategies that reduce illumination loads.

3. Building-integrated photovoltaics. In recent years, BIPV systems have shown signs of living up to their promise. With improvements in thin-film PV products to performance levels needed for use in vision glazing, they are getting closer to those of solid solar cells, used in spandrels and shading devices.

Façade orientation and inclination angle are both crucial to the successful integration of PV technology, and the improvement of thin films means that more of a project’s façade area can be integrated for solar harvesting without sacrificing transparency or translucence. Of course, BIPV is an energy-producing technology, not an energy-managing one: Passive solar, which works by managing the temperature of internal thermal mass, according to Cousins, is more closely associated with energy-managing techniques.

One cutting-edge technology is the integrated concentrating solar façade, or ICSF, currently in development by the Center for Architecture Science and Ecology (http://www.case.rpi.edu), a collaboration between Rensselaer Polytechnic Institute and Skidmore, Owings & Merrill. This is a dynamic façade system composed of moving gem-like solar collectors that can harvest daylight and fulfill a number of other energy requirements—heating, cooling, hot water, and electricity production.

4. Phase-change materials. PCMs are solid at room temperature but liquefy at higher temperatures, absorbing and storing heat in the process, says Aksamija. They are currently commercially available integrated into IGUs. Composed of either waxes or salts, PCMs can absorb high exterior temperatures by day and emit the heat to the interior at night.

5. Aluminosilicate glass, which is used to cover the displays of personal digital devices, is extremely thin and highly impact resistant. This glass type is essentially unheard of in building applications, because manufacturing large spans of the glass is prohibitively expensive. However, manufacturers are investing in improving the process because thin, impact-resistant glass could be an enormous boon to architectural glazing.

6. ETFE. Ethylene tetrafluoroethylene is a fluorine-based plastic originally conceived for its anti-corrosive properties, but which also demonstrates benefits for glazing applications, namely low weight, recyclability, and, in double- and triple-ply configurations with a gas fill, excellent thermal properties. But pumps are required to maintain constant air pressure relative to varying wind loads, and (worst-case scenario) when it burns the material releases hydrofluoric acid, which is highly toxic and corrosive.

Editor's note: This article was adapted from our recent AIA CES Discovery course, "Energy-efficiency Glazing Technology." Take the free course.

Related Stories

Airports | Sep 18, 2020

Wings clipped, airports veer to tech to regain passenger trust

Alternative project delivery methods are also being considered.

Airports | Sep 10, 2020

The Weekly show: Curtis Fentress, FAIA, on airport design, and how P3s are keeping university projects alive

The September 10 episode of BD+C's "The Weekly" is available for viewing on demand.

Giants 400 | Aug 28, 2020

2020 Giants 400 Report: Ranking the nation's largest architecture, engineering, and construction firms

The 2020 Giants 400 Report features more than 130 rankings across 25 building sectors and specialty categories.

Airports | Jul 28, 2020

CallisonRTKL to design one of the world’s first net-zero airports

Guadalajara Airport Terminal 2 will be designed from the ground up.

Coronavirus | Jul 20, 2020

Student housing amid the pandemic, infection control in buildings, and future airport design on "The Weekly"

Experts from Core Spaces, Bala Consulting Engineers, and Populous were interviewed in the July 23 streaming program from Horizon TV.

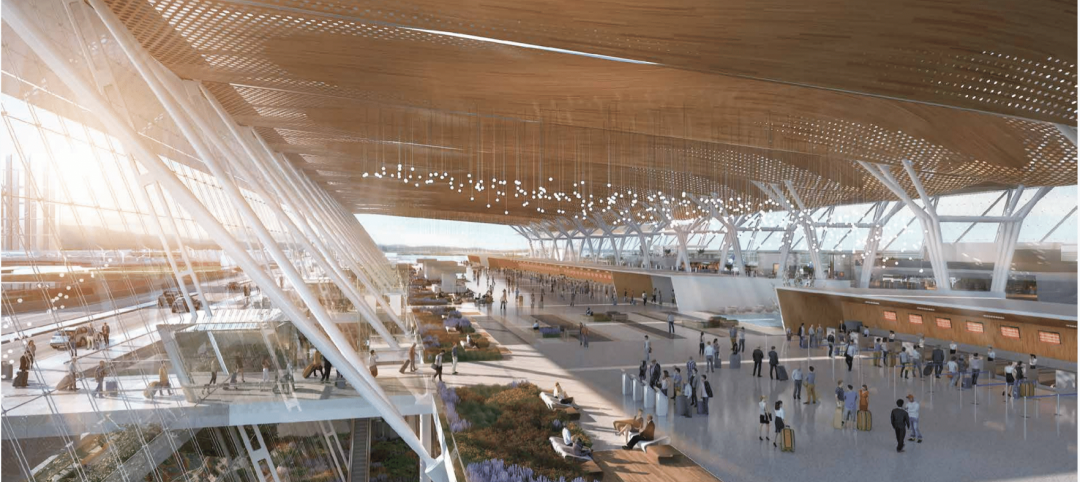

Airports | Jun 24, 2020

LaGuardia Airport’s Terminal B officially opens

HOK and WSP USA designed the project.

Airports | Feb 7, 2020

A 780-ft-long pedestrian walkway is positioned over an active taxi lane at Sea-Tac International

It took eight years to plan, design, and construct this bridge.

Airports | Nov 12, 2019

$1B terminal opens at New Orleans International Airport

LEO A DALY designed the project.

Airports | Oct 30, 2019

COX Architecture and Zaha Hadid Architects will design the Western Sydney Airport

The COX/ZHA team was selected from a field of over forty applicants.

Giants 400 | Oct 25, 2019

Top 55 Airport Sector Construction Firms for 2019

Hensel Phelps, AECOM, Turner, Skanska, and PCL top the rankings of the nation's largest airport terminal sector contractors and construction management firms, as reported in Building Design+Construction's 2019 Giants 300 Report.