|

| Cisterns and tanks for rainwater harvesting are becoming a familiar sight on many properties. The tanks can also be buried underground to increase available developable area. For residential and light commercial applications, slim pre-engineered tanks reduce the amount of space required. |

In the U.S. and most of the industrialized world, building occupants take for granted the simple convenience of filling a glass with clean, drinkable water at the kitchen sink. Yet worldwide, nearly a billion people globally have no access to safe drinking water, according to the Natural Resources Defense Council. Americans use an average of 100 gallons of fresh water each day, with a total 4.8 billion gallons a day going down the drain. Furthermore, a 2003 survey by the U.S. Environmental Protection Agency (EPA) revealed that at least 36 states could suffer local, regional, or statewide water shortages by the year 2013.

Water also needs to be transported and treated, meaning that each drop of water represents some expenditure of energy. Public water supplies and treatment facilities in the U.S. consume an average 56 billion kilowatt-hours (kWh) a year—enough electricity to power more than five million homes for an entire year. Moreover, the EPA reports that approximately 4% of the nation's electricity consumption is used for moving or cleaning water and wastewater.

The growing awareness of the planet's limited resources and the rapid expansion of the green building movement are compelling Building Teams to employ more water-conserving strategies and plumbing technologies. From rainwater harvesting and graywater recycling systems to integrated water-metering “dashboards,” the possibilities are not only intriguing but suggest a manageable and sustainable future.

|

|

| Before-and-after photos of a rainwater harvesting system designed for UNUM Insurance’s corporate headquarters in Chattanooga, Tenn. The system provides an average 7,950 gallons per week to the facility. |

HARVESTING RAINFALL

Although collecting rainwater in wooden barrels and cisterns for use in drinking and washing goes back centuries, modern systems offering much greater efficiencies, savings, and sanitary protection are just now growing in popularity. Irrigation is the most common application, but harvested rainwater is also being channeled into a whole host of uses, including toilets and urinals, laundry facilities, cooling towers, and sewage conveyance. In specialized applications with intensive water use, harvest rainwater is being used for manufacturing processes, car washing, food processing, and agricultural wash-down systems.

According to Stephen White, ASLA, LEED AP, manager of landscape architecture at the Albert Kahn Family of Companies (www.akahn.com), Detroit, the main components of a rainwater harvesting system are:

The storage device, such as a tank, cistern, or detention pond.

The filtration apparatus.

Monitoring and controls equipment.

A critical component of rainwater harvesting is prefiltration. Before the water runs into the storage system, it initially falls upon surfaces such as rooftops, parking lots, and landscapes areas, and then goes through the prefiltration process. “The newer rainwater harvesting systems utilize a device to divert the first flush of rainwater, which often contains dust, dirt, and pollen that has settled on roof or drainage areas,” says veteran plumbing engineer Ron George, CIPE, CPD, president of Ron George Design & Consulting Services (www.rongeorgedesign.com), Monroe, Mich. “After a predetermined amount of rainwater has flowed through the diversion device, the rainwater is then directed to a cistern or holding tank.”

Sizing and selecting the prefiltration device is directly related to the surface material and area of collection.

“Screen filters can be located above or below ground and usually filter the water to the 400-700 micron level,” says Mike Warren, a senior design engineer with Watertronics, Inc., a Wisconsin-based manufacturer of rainwater-harvesting systems. The screen filters employ a coarse mesh that catches larger sediments and the like. “Another type of filtration that may be required is oil, water, and grit separation,” says Warren, who has designed more than 1,800 pumping and control systems in his career. “When collecting water from a parking lot, there is always the potential for hydrocarbons to enter the storage vessel. Oil/water separators can be designed into tanks or as separate systems, and the control logic may include a hydrocarbon monitor to protect or alarm the user should the water become contaminated.”

Rainwater storage. Moving on to the storage system, Warren explains that tank size is determined by the volume of rainwater collection, frequency of use, and budget. Tanks can range in size from 5,000 gallons to up to 200,000 gallons or more. Available in a variety of materials, shapes, and configurations, rainwater storage components vary greatly in performance. Warren stresses the importance of choosing a durable system, especially for below-ground installations.

|

This small, point-of-use graywater system funnels used water from the lavatories through a sanitizing device that cleans and fi lters the water. The liquid then sits in a storage reservoir under the sink until the toilet connected to the system flushes, causing a pumping of the water from the reservoir to the flush tank. |

While detention ponds are also an option for storage, Albert Kahn's White is not a big fan. “Ponds have limited potential for water reuse as they are susceptible to contamination and sediment loading, and they are limited to the ground plane,” he says. “In addition, the source for reuse is often a great distance from the site's stormwater pond.”

Pumping and controls. Also distinguishing the old-fashioned cistern-and-pipe systems from modern-day rainwater operations are the pumping and control systems. Most commonly, centrifugal pumps are specified, along with a variable-frequency drives (VFDs) for applications where water usage varies, such as in toilet flushing. With VFDs, “The end result is a system that regulates a constant pressure to the end user at a variable flow rate without the use of inefficient valves or wasting of energy,” says Warren, who teaches continuing-education courses on water harvesting, water controls, and pumping applications.

It is also important to make sure that the pumping control equipment is properly designed for the specified rainwater-harvesting system. “Just having a box of parts show up on your doorstep that you have to figure out how to put together almost always results in a poorly operating system,” says Warren.

|

A mock-up of a “bioregional dashboard” shows how it will display environmental conditions to inform water resource use. As part of the Great Lakes Protection project, a team of Oberlin College professors, municipal officials, and a building-dashboard design group are collaborating to roll out real-time metering to motivate conservation in the Great Lakes region. |

Warren also emphasizes the importance of configuring the controls to optimize the available storage volume—and to switch to backup water supplies, if necessary. “Controls need to shut the system down when it's out of water, and also to re-enable itself automatically when water is present, but still allow for the most available volume to harvest the next rain event,” he says. “The system must also determine when to allow the backup water to be used and when to switch back to rainwater.”

The way this works, says Don Jones, AIA, LEED AP, director of sustainable design with EwingCole (www.ewingcole.com), headquartered in Philadelphia, is by wiring a float or electronic level detector in the cistern to a digital control system. “This in turn controls a solenoid valve that, when triggered by low rainwater level, switches the system to a domestic water backup source until the rainwater cistern is replenished,” says Jones.

Warren points out another benefit of smart controls: They offer “a valuable return on investment and water-savings data, allowing the owner to quantify exactly how many gallons of water are being saved per month and per year.”

Post-filtration. Finally, a post-filtration system is useful for applications requiring a higher level of purification, such as process water or even potable water. In most cases, however, city and state code regulations will dictate the level of water quality. For example, sometimes ultraviolet lamp filters are required, which then necessitate a very fine screen filter just upstream; others may require chlorine injection to kill any bacteria in the water line. “It is important that the control and monitoring of these filters be integrated into the rainwater harvesting control panel should one of them fail,” says Warren.

In addition, other projects may require dye injection to identify the water as nonpotable in the building's plumbing system.

With an eye toward minimizing operations and maintenance issues, the facility management team should check regularly to ensure that the system's filters are serviceable, the storage tank is clear of dirt and debris, and motor bearings are properly oiled. In cold climates, the systems sometimes need to be drained and then started up again in the spring.

With the exception of smaller and more simplified residential setups, rainwater harvesting systems are generally engineered systems customized specifically for each project's unique requirements. “While many companies offer packaged systems that are viable to be implemented, a skilled and experienced design firm should be engaged in order to ensure that the systems is properly integrated into the site,” states Kevin Poffenbarger, PE, a senior project engineer with EPD Consultants (www.epd-net.com), a San Pedro, Calif.-based firm specializing in graywater, rainwater collection, and stormwater management design.

David C. Smith, PE, a plumbing and fire-protection department manager with Bala Consulting Engineers (www.bala.com), King of Prussia, Pa., points out that the current lack of standards makes customization for commercial projects a greater necessity. He notes, however, that both Texas and Virginia offer rainwater harvesting manuals, while the American Rainwater Catchment Systems Association (www.arcsa.org) and the American Society of Plumbing Engineers are currently in the process of developing design and installation standards.

Return on investment (ROI). While rainwater reuse initially sounds like an efficient and sustainable approach, assuring and measuring its ROI are often not so straightforward. “The payback needs to be calculated based on the cost of water, the amount of average rainfall in an area, and the size and cost of the system,” says consultant Ron George, who sits on numerous codes and standards committees related to plumbing and mechanical systems.

In general, the more sophisticated the system, the higher the first cost. “And due to the current cost of water, paybacks may be lengthy,” cautions White. Warren also acknowledges that the low cost of water typically will not produce a robust ROI, especially with large variances in price, from $1.00 for 1,000 gallons in Wisconsin, all the way up to $10.00 for 1,000 gallons in Washington, D.C.

“The biggest paybacks come into play when you can save land value by burying a tank, or when you may have large tax incentives to retain rainwater that falls on the property,” says Warren.

One variable which may change the ROI equation is new legislation being considered in some cities. Richmond, Va., is considering charging property owners for allowing rain that falls on their properties to run down into the city sewer system.

Still, the biggest unknown factors that make ROI difficult to calculate are the price of water—will it increase, and by how much?—and the amount of rainfall.

REUSING BUILDING WATER

While the amount of rainfall may be impossible to predict, the volume of water use in buildings is fairly easy to determine based on average building occupant needs and behaviors. For that reason, inventing more efficient ways to benefit from reused water has been a focus for many years now. Graywater refers to wastewater from lavatories, bathtubs, showers, and washing machines that is collected, filtered, and treated for reuse within the same property, primarily to flush toilets, before being sent to the sewage treatment facility. Blackwater is wastewater from toilets and kitchen sinks that is collected and treated by municipal facilities and returned to buildings via “purple pipes” (which are separate from pipes carrying potable water) for use in irrigation or cooling-tower water regeneration.

The main engineering and health challenge of reuse is treatment, according to David DeBord, CPD, LEED AP, a senior associate with Environmental Systems Design (www.esdesign.com, ESD), Chicago. “Graywater reclamation systems are more complex than rainwater systems due to increased biological and chemical materials in the water to be treated,” he points out.

Perhaps a more accurate description of the technology is on-site reclaimed water treatment system, says Shawn Martin, until recently the technical director of the Plumbing Manufacturers Institute (www.safeplumbing.org), Rolling Meadows, Ill., and now director of industry relations for ICC Plumbing, Mechanical & Fuel Gas, Whittier, Calif. “The reason is that these devices, which are essentially appliances, can accept a range of nonpotable water inputs, and output water treated to a predetermined level of purity,” he says. “Inputs to these devices can include untreated graywater, rainwater, foundation drain water, and air-conditioner condensate.”

While commonly used for subsurface drip irrigation, the reclaimed water can also be used for flushing toilets, construction site processes, concrete mixing, and cooling water for power plants.

In addition, EPD Consultants' Poffenbarger points out that because graywater is generated on a daily basis, as opposed to seasonally, it is often a more reliable source of reusable water than stormwater. A recent demonstration project for on-site reclaimed water treatment sponsored by the Canada Mortgage and Housing Corporation found that graywater toilet flushing reuse for a 20-unit apartment building in North Vancouver, B.C., reduced water demand—and costs—by about 40%. In addition, the size and cost of the on-site wastewater treatment and disposal system was reduced due to the projected drop in demand.

On a smaller scale, a hotel in Big Sur, Calif., was spending a few thousand dollars a month to outsource its laundry because the conventional on-site disposal system couldn't handle the water. After building a new reclaimed water system, the laundry operation was brought in-house. The investment paid for itself in less than a year, which raises the prospect of using graywater systems to achieve water-use efficiencies (and dollar savings) for other water-intensive building occupancies.

System components. In general terms, Poffenbarger describes a basic graywater system as a separate plumbing tree inside a building, with a three-way valve outside the building to divert the reclaimed water. Other requisite components include a pre-filter, a graywater surge/filtration tank with overflow to the sewer, a graywater pump with a post-filter, and (if applicable) a subsurface irrigation system.

The ICC's Martin describes several additional treatment system components:

Intermediate/fine filter or separator. This assembly filters the water further, as needed, for the treatment system and end use.

Initial water treatment. To disinfect the water, the first process will inactivate, absorb, or physically remove bacteria and other microorganisms through a variety of mechanisms such as chlorine, chloramine, hydrogen peroxide, ozone, ultraviolet (UV) light, or a combination of these.

Secondary water treatment. Depending on the initial water treatment technology and end-use needs, some systems employ secondary treatments to affect other water quality parameters such as hardness, dissolved solids, turbidity, and pH.

Storage. Treated water is stored in a vessel to make it available for use within the building or on the site. Water quality must be maintained to avoid the regrowth of microorganisms.

In terms of treating the water, chlorine and chloramine are most commonly used; however, these chemicals can be highly corrosive at excessive levels, and their production processes and by-products are environmentally undesirable, according to Shawn Martin, who serves as a consensus committee member of the ANSI-accredited National Green Building Standard, currently under development.

The advantage of going with a UV light or ozone system is the high level of effectiveness both systems provide in destroying a wide spectrum of microbes; in addition, these systems will not affect the water quality, nor do they need to be refilled. On the other hand, their effectiveness diminishes with age; with UV technology, the bulb needs to be monitored and replaced periodically. Moreover, according to Martin, there is “no residual effect, therefore the water can immediately begin to regrow microbes immediately after leaving UV exposure.” As for ozone, Martin notes, “Undissolved ozone bubbles, which are highly corrosive and destructive to many materials, can accumulate in systems. Ozone is a respiratory irritant if introduced into the user environment, and is heavier than air.”

In terms of sizing the systems, consultant Ron George recommends that the system piping follow the fixture unit sizing charts included in model plumbing codes. “Each graywater system must be designed and piped based on the layout of the fixtures that discharge graywater,” he advises. The treatment equipment is available in small and large package systems, and the systems can be site-built out of tanks and components, he notes.

While plumbing fixtures, drains, appurtenances, and appliances used to receive or discharge liquid wastes or sewage need to be directly connected to the sanitary drainage system of the building or premises—in accordance with the requirements of the applicable plumbing code—an exception exists for bathtubs, showers, lavatories, clothes washers, and laundry trays that discharge to an approved graywater system, explains George.

As is the case with rainwater harvesting systems, EPD Consultants' Poffenbarger recommends bringing in a qualified consultant/designer to integrate the reclaimed water system with the stormwater cistern system. This also involves addressing health department concerns regarding cross-connections with the municipal water supply.

As for first cost, George points out that a graywater system with its separate piping system, filters, holding tanks, and treatment systems runs about twice the cost of a conventional sanitary waste-and-vent system. For example, the added expense involved in designing a dual-piping system for fresh and recycled water can tack on about 9% to the plumbing expenses for a new building of seven stories or more, according to the Irvine, Calif., Ranch Water District.

“Payback is typically long-term and is not economically feasible with most water utility rates,” notes George. “However, it does reduce water usage and can earn LEED points for water use reduction.”

One other impediment to greater market penetration is the current lack of a water-quality standard for these systems. While municipally supplied reclaimed water is subject to local water-quality requirements, this is generally not the case for on-site reclaimed water systems. “The closest guidance is the 2004 EPA Reclaimed Water Guidelines, but they are only recommendations, and only address health and safety concerns, not suitability of use,” says the ICC's Martin.

At the moment, a task group from the nonprofit product certification entity NSF International, Ann Arbor, Mich. (www.nsf.org) is working on just such a standard. “It is the hope of the industry that this document will be completed promptly,” says Martin.

MONITORING CONSUMPTION

While rainwater harvesting and reclaimed water systems show promise, perhaps the most common application of water-saving plumbing technologies has been no-flow and low-flow fixtures. However, experts say that the industry may be reaching the upper limit on how efficient point-of-use fixtures can become.

David N. Holst, a senior plumbing/fire protection engineer with Bala Consulting Engineers, King of Prussia, Pa. (www.bala.com), sees water metering as the next big trend. Through the application of what Holst calls “building dashboards” that display real-time resource use, trends, and anomalies on a graphical display, end users could be educated and even socially motivated to conserve resources.

For example, students in 17 residence halls at Oberlin College, Oberlin, Ohio, participated in a two-week competition to conserve resources, guided by real-time energy and water-use metrics displayed on a building dashboard. The winning residence hall succeeded in reducing water consumption by 11%, while overall water savings for all 17 residential facilities amounted to about 20,500 gallons during the 14-day test period. (It should be noted that total energy-use reduction was much more significant, at 32%.) Strategies for water conservation included ensuring that faucets were not dripping, taking shorter showers, turning off water while brushing teeth, washing clothes less often, taking fewer showers, and flushing toilets less frequently.

“We believe that the combination of social, environmental, and economic context has been crucial to the success the building dashboard technology has achieved with electricity, and we believe the same thing will be true for water,” says John Petersen, an associate professor of environmental studies and biology director for Oberlin's environmental studies program. The success of more transparent water metering will be motivated by pure economics (saving money on utility bills) as well as the pressures of social competition and the occupants' desires to achieve an environmental sense of satisfaction by using less water, says Petersen.

Although data visualization applications like those at Oberlin are now being developed by the industry and implemented in building projects, it is still very cutting-edge. However, David Lehrer, director of communications for the Center for the Built Environment at the University of California, Berkeley, sees building information visualization as an area that will see significant growth in the near future.

In an effort to encourage the adoption of the technology, a team of Oberlin College professors, Oberlin city officials, and a building-dashboard design group were recently awarded a grant from the Great Lakes Protection Fund to implement real-time resource use metering to motivate conservation in the Great Lakes region.

“Displaying water use is also an absolutely central component of our work on the Great Lakes Protection Fund grant that we are now embarking on in which we will monitor and display individual residents' and businesses' water use and also total water flow through the wastewater treatment plant, freshwater treatment plant, and local river system, as well as water quality in the wastewater effluent and river system,” says Petersen, who is heading the project.

On a smaller scale, another project at Oberlin College involves the monitoring and display of water use and water treatment at the Lewis Center for Environmental Studies. (Real-time metrics from the facility can be viewed online at www.oberlin.edu/ajlc.) A second project in the works involves designing separate monitors for hot- and cold-water use in a new Oberlin residence hall. “Typically, we have only been able to easily monitor total water consumption for a dorm, so this fine scale of resolution creates new opportunities,” says Petersen.

In terms of obstacles to a broader-scale implementation of the technology, Petersen sees the necessity of being able to monitor to this higher degree of resolution—for example, to be able to track water usage down to the gallon. In the Great Lakes project, for example, the technology currently gathers data from utility water meters in 100-gallon increments, which is typical of today's available systems. Says Petersen, “This may be fine for monthly billing data, but you can't use these data to create a display that allows consumers to understand patterns of water use that occur when they shower, do laundry, wash dishes, or even water their lawn.”

Consequently, it is Petersen's hope that the industry will begin recognizing the importance of such high-resolution data and encourage utilities to install meters capable of monitoring to much lower levels, even down to the one-gallon level.

HEATING AND USING WATER AS NEEDED

Demand reduction for water use in buildings occurs at the point of use, as well as on a system-wide level. Beyond the more broad-scale systems discussed above, a few sustainable plumbing technologies that are smaller and more easily deployed include tankless or instantaneous water heaters, as well as new developments with waterless urinals and composting toilets.

“Tankless water heaters expend energy on an as-needed basis,” explains Leonard Mecca, a plumbing designer with EwingCole, Philadelphia. “They do not store domestic hot water, and therefore do not have to expend energy on a constant basis to maintain [a steady] temperature of stored water.” Moreover, their small, compact size saves floor space, and they can even be wall-mounted.

However, some consultants, including Ron George, say that tankless appliances are limited in their performance, particularly when connected to hot-water systems with multiple fixtures. In these cases, hot-water demand can easily exceed the unit's capacity to instantaneously heat water, generally through a coil of copper or a metal alloy. He adds that some instantaneous heaters will raise the water temperature by only 35 to 50 degrees Fahrenheit, which in most northern climates may not be hot enough to result in a comfortable shower. Another concern: “Most instantaneous electric heaters utilize a flow-control valve to reduce the flow to a point where the water is warm, but if the flow is too low, the flow switch will not operate and the water will come out cold,” says George.

As for gas heaters, they are rather pricey—three to four times more than a conventional storage-type heater—and, according to George, may not achieve a good payback over an appliance's lifetime. There are also technical limitations: “The gas-fired heaters measure the outlet temperature of hot water, and they have an automatic control valve to throttle the flow down to a point where it maintains a minimum set temperature. The problem is the throttling valve often causes pressure fluctuations in the piping system that can cause thermal shock in a shower.”

However, George does acknowledge that there seems to be significant industry interest in instantaneous water heaters, and that they can be a good choice for remote installations with a single fixture.

Another strategy, according to ESD's DeBord, is combining the heaters with a solar thermal domestic water-heating system. This way, even more environmental benefits can be reaped from the tankless heaters.

In one recent project—a large manufacturing facility—the Kahn firm installed the water heaters in an employee shower area. In addition to eliminating heat loss from the storage tank, associated energy usage was reduced. “The domestic hot-water heating system was able to provide a great turndown ratio under low-flow conditions, which allowed only the water that was instantaneously needed to be heated,” explains Mecca.

At the same, despite the fact that these water heaters are available in sizes approaching 400,000 Btu per hour—large enough, for example, to serve a number of hotel guestrooms—a large number of heaters were still required for this project. This was due in part to the fact that the tankless heaters had to be sized to meet the anticipated peak load, whereas conventional heaters can tap into their storage to meet a large load of short duration.

Waterless restroom fixtures. Restroom design, unlike water heating, has tended to get more publicity for green technologies, in part because it is a high-visibility area that affects all building occupants. One of the more controversial has been the development of waterless urinals. The technology continues to be tweaked with different cartridges and liquid seals that occasionally come on the market. Of note is a relatively new offering that enables conventional urinals to operate largely water-free.

While waterless urinal units work chemically—typically using a sealing oil inside a trap that captures odor inside—the newer products (one brand of which, the EcoBlueCube, is described at www.ecobluecorp.com) work biologically. A two-inch square, placed on the drain, employs a substance called “beneficial bacteria,” which works to break down the liquid waste and eliminate odor. By slowing releasing the bacteria, a bio-film begins to line the bowl, trap, and pipes. The multiplying bacteria then metabolize the uric acid in the waste, and a perfume odor is released from the square. The urinal is flushed once or twice a day for maintenance to retain its freshness, and the cube is changed out every week or so, depending on frequency of use. According to media reports, the cube can save $500 a year in water costs, or as much as 25,000 gallons of water per month for each fixture.

The broader trend for traditional waterless urinals, George points out, is that they're now being accepted into most model codes. However, in order to maintain sanitation and high-quality operations, the fixtures demand strict maintenance practices. “If the fixtures are not routinely cleaned with a spray bottle, odors can develop in the room,” says the consulting engineer. “In addition, a small amount of water is required to be poured into the fixture on a regular basis to wash urine salts down the drain, but if too much water is dumped into a non-water-using urinal, it can flush the sealing oil down the drain, allowing odors to develop.”

George also warns against replacement cartridges utilizing a rubber valve, which have recently entered the market. He points out that most manufacturers are voiding their fixture warranties if the rubber valve traps are used, in addition to the fact that the traps may not meet plumbing code requirements.

Another noteworthy development that has begun appearing as proposals to green and plumbing codes, according to PMI's Martin, involves the installation of one or more lavatories upstream of any waterless urinals. “This ensures that drainage lines leading from the urinal receive a certain amount of wastewater flow and flush the drainage lines to avoid buildups and blockages,” he says. This practice is recommended in the forthcoming Green Plumbing and Mechanical Code Supplement, which is scheduled for release in February 2010 by the International Association of Plumbing and Mechanical Officials (www.iapmo.org).

Composting toilets. Although the recent introduction of toilets that biologically decompose waste into nutrient-rich compost for use as fertilizer has been traditionally aimed at users such as rural parks, cabins, and highway rest stops, newer designs of composting toilets are enabling the luxury of indoor installations in denser settings.

This is welcome news in sustainability circles. “Composting toilets offer the potential to save water and recycle a valuable resource,” says EPD Consultants' Poffenbarger.

The U.S. Green Building Council's LEED rating systems recognize the benefits of composting toilets, offering them as one of the ways to achieve required water reduction levels. (LEED has recently tightened its water-reduction requirements to 20% for indoor potable use, with a 30% reduction required before any points are awarded in the latest version, LEED 2009.)

Another noted improvement has been the successful elimination of odors in modern-day units, thanks to carefully designed airshafts and venting. For example, one manufacturer has engineered the airflow to maintain a partial vacuum within the unit at all times. In other words, air is either continuously being drawn by a fan or vent chimney over the evaporating chamber and up the vent stack. In addition to evaporating the liquid waste, the constant pressurized airflow ensures that no odors escape from the unit.

Even so, consultant Ron George says he does not anticipate broader acceptance in the commercial market for composting fixtures, noting that their application complicates building operations. In a similar vein, Poffenbarger points out, “The process of removing the compost offers a potential risk to public health, albeit minimal, and this has unfortunately impeded larger-scale use of these systems.”

Such challenges have done little to impede the growing interest in water-conservation technologies. In fact, Building Teams across the country are preparing to redouble their efforts for incorporating water efficiency into their projects.

According to the United Nations press agency, MaximsNews Network, President Obama has expressed interest in policies to encourage water conservation and waste reduction, as well as increased R&D investment for technologies related to water use reduction (http://www.maximsnews.com/news20080927obamamccainwater10809270801.htm).

Such an effort, coupled with water resource management and new supply options such as desalination in arid regions, will be critical for assisting high-growth regions that may be facing water shortages in coming decades.

| Diameter of pipe (mm) | Average rate of rainfall in mm/h | |||||

| Source: National Building Code | ||||||

| 50 | 75 | 100 | 125 | 150 | 200 | |

| 50 | 13.4 | 8.9 | 6.6 | 5.3 | 4.4 | 3.3 |

| 65 | 24.1 | 16.0 | 12.0 | 9.6 | 8.0 | 6.0 |

| 75 | 40.8 | 27.0 | 20.4 | 16.3 | 13.6 | 10.2 |

| 100 | 85.4 | 57.0 | 42.7 | 34.2 | 28.5 | 21.3 |

| 125 | - | - | 80.5 | 64.3 | 53.5 | 40.0 |

| 150 | - | - | - | - | 83.6 | 62.7 |

Related Stories

Industrial Facilities | Apr 9, 2024

Confessions of a cold storage architect

Designing energy-efficient cold storage facilities that keep food safe and look beautiful takes special knowledge.

AEC Innovators | Feb 28, 2024

How Suffolk Construction identifies ConTech and PropTech startups for investment, adoption

Contractor giant Suffolk Construction has invested in 27 ConTech and PropTech companies since 2019 through its Suffolk Technologies venture capital firm. Parker Mundt, Suffolk Technologies’ Vice President–Platforms, recently spoke with Building Design+Construction about his company’s investment strategy.

MFPRO+ Special Reports | Feb 22, 2024

Crystal Lagoons: A deep dive into real estate's most extreme guest amenity

These year-round, manmade, crystal clear blue lagoons offer a groundbreaking technology with immense potential to redefine the concept of water amenities. However, navigating regulatory challenges and ensuring long-term sustainability are crucial to success with Crystal Lagoons.

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Building Tech | Feb 20, 2024

Construction method featuring LEGO-like bricks wins global innovation award

A new construction method featuring LEGO-like bricks made from a renewable composite material took first place for building innovations at the 2024 JEC Composites Innovation Awards in Paris, France.

Modular Building | Jan 19, 2024

Building with shipping containers not as eco-friendly as it seems

With millions of shipping containers lying empty at ports around the world, it may seem like repurposing them to construct buildings would be a clear environmental winner. The reality of building with shipping containers is complicated, though, and in many cases isn’t a net-positive for the environment, critics charge, according to a report by NPR's Chloe Veltman.

Sponsored | BD+C University Course | Jan 17, 2024

Waterproofing deep foundations for new construction

This continuing education course, by Walter P Moore's Amos Chan, P.E., BECxP, CxA+BE, covers design considerations for below-grade waterproofing for new construction, the types of below-grade systems available, and specific concerns associated with waterproofing deep foundations.

Mass Timber | Jan 2, 2024

5 ways mass timber will reshape the design of life sciences facilities

Here are five reasons why it has become increasingly evident that mass timber is ready to shape the future of laboratory spaces.

Sustainability | Nov 1, 2023

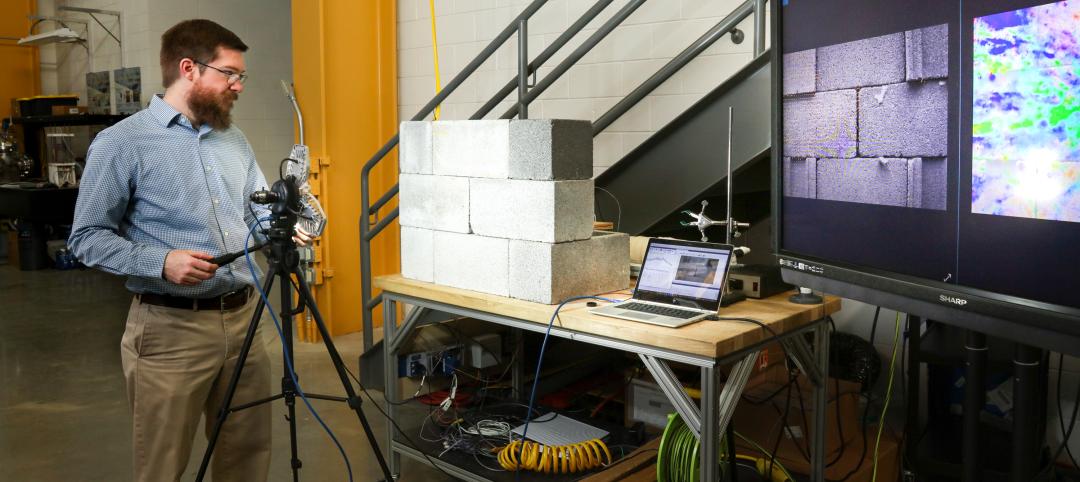

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

Engineers | Oct 12, 2023

Building science: Considering steel sheet piles for semi-permanent or permanent subsurface water control for below-grade building spaces

For projects that do not include moisture-sensitive below-grade spaces, project teams sometimes rely on sheet piles alone for reduction of subsurface water. Experts from Simpson Gumpertz & Heger explore this sheet pile “water management wall” approach.