As architectural teams continue to push the limit of building design with ever more complex geometries, engineering and construction firms must develop clever solutions to execute these daring schemes on time and within budget.

During the course of several recent projects, engineers with Simpson Gumpertz & Heger (SGH) and fabricator CW Keller have created an integrated approach to model, design, and off-site fabricate formwork for complex concrete geometries. The process combines SGH’s expertise with concrete materials, construction, and analysis of intricate assemblies, with CW Keller’s advanced modeling and computer numerically controlled (CNC) fabrication capabilities, to create geometrically complex, prefabricated formwork systems.

“The combination of advanced CNC machining and emerging technologies in construction materials is pushing the bounds of what can be cost-effectively constructed in concrete,” says Matthew Johnson, Principal with SGH. Johnson says the two disciplines—structural engineering and formwork fabrication—work hand in hand since the fabrication model can serve as the basis of analysis models. As a result, “teams can assess many options early and rapidly,” he says.

On the team’s most recent project, the new Gulf Stream Tank at the Patricia and Phillip Frost Museum of Science in Miami (pictured above), the prefab process saved roughly nine weeks of the project schedule compared with conventional site-constructed formwork. The elevated tank structure is 125-foot-diameter, conical, cast-in-place concrete construction. It will hold more than 500,000 gallons of seawater, and will feature an acrylic oculus to offer museum visitors views into the tank from below.

Also on the Building Team: Grimshaw (architect), Baker Concrete Construction (concrete subcontractor), Peri (shoring contractor), and Skanska (GC).

Photo: CW Keller

Photo: CW Keller

Photo: CW Keller

Photo: CW Keller

Rendering: Grimshaw

Rendering: Grimshaw

Related Stories

75 Top Building Products | Apr 22, 2024

Enter today! BD+C's 75 Top Building Products for 2024

BD+C editors are now accepting submissions for the annual 75 Top Building Products awards. The winners will be featured in the November/December 2024 issue of Building Design+Construction.

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Sustainability | Nov 1, 2023

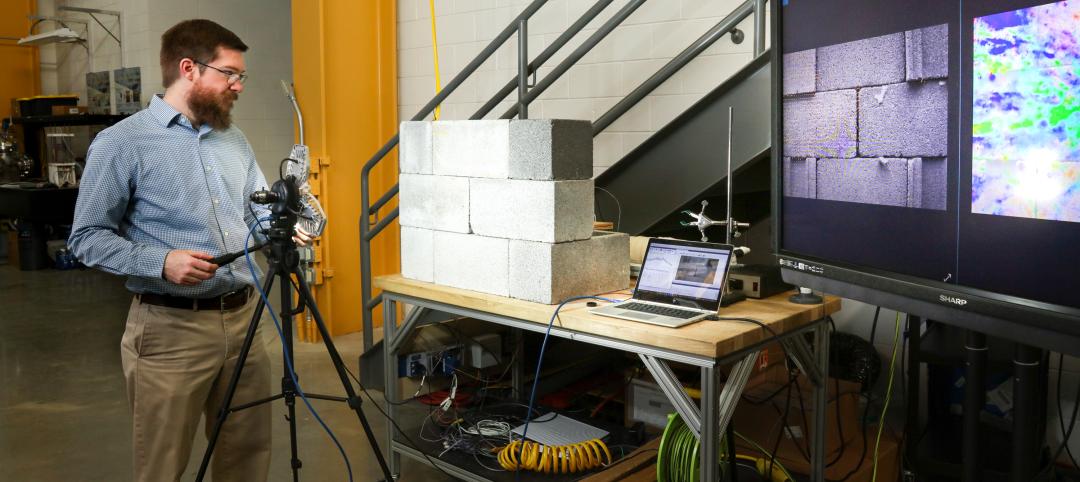

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

Resiliency | Aug 7, 2023

Creative ways cities are seeking to beat urban heat gain

As temperatures in many areas hit record highs this summer, cities around the world are turning to creative solutions to cope with the heat. Here are several creative ways cities are seeking to beat urban heat gain.

AEC Innovators | Jun 15, 2023

Rogers-O'Brien Construction pilots wearables to reduce heat-related injuries on jobsites

Rogers-O'Brien Construction (RO) has launched a pilot program utilizing SafeGuard, a safety-as-a-service platform for real-time health and safety risk assessment. Non-invasive wearables connected to SafeGuard continuously monitor personnel to prevent heat exhaustion on jobsites, reducing the risk of related injuries. RO is the first general contractor to pilot this program.

Office Buildings | May 15, 2023

Sixteen-story office tower will use 40% less energy than an average NYC office building

This month marks the completion of a new 16-story office tower that is being promoted as New York City’s most sustainable office structure. That boast is backed by an innovative HVAC system that features geothermal wells, dedicated outdoor air system (DOAS) units, radiant heating and cooling, and a sophisticated control system to ensure that the elements work optimally together.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

Design Innovation Report | Apr 19, 2023

Reinforced concrete walls and fins stiffen and shade the National Bank of Kuwait skyscraper

When the National Bank of Kuwait first conceived its new headquarters more than a decade ago, it wanted to make a statement about passive design with a soaring tower that could withstand the extreme heat of Kuwait City, the country’s desert capital.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.